Carbon is allowed to diffuse through a steel, a process that significantly influences the material’s properties and performance. This article delves into the mechanisms, effects, and applications of carbon diffusion in steel, providing a comprehensive overview of this important metallurgical phenomenon.

Carbon diffusion plays a crucial role in shaping the mechanical properties, microstructure, and overall quality of steel. Understanding the principles and applications of carbon diffusion is essential for engineers, metallurgists, and materials scientists involved in the production and utilization of steel.

Carbon Diffusion Mechanisms

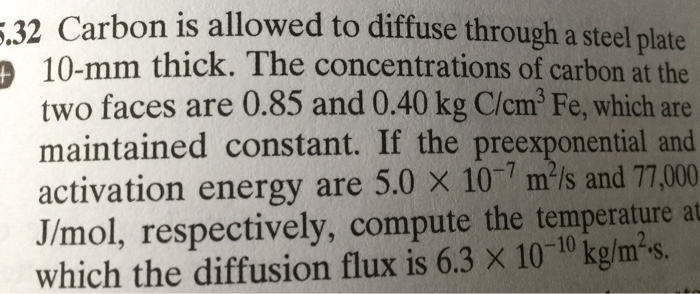

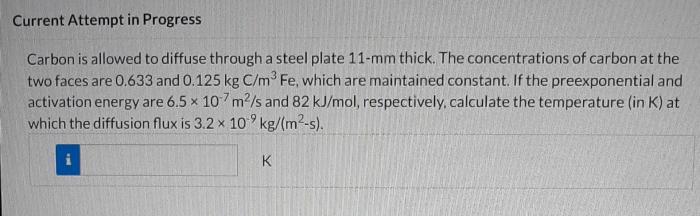

Carbon diffusion in steel is a complex process involving the movement of carbon atoms within the steel’s microstructure. It occurs when there is a concentration gradient of carbon, with carbon atoms moving from areas of high concentration to areas of low concentration.

The rate of carbon diffusion is affected by several factors, including temperature, the presence of alloying elements, and the microstructure of the steel.There are several different mechanisms by which carbon can diffuse through steel. These mechanisms include:

- Interstitial diffusion:In this mechanism, carbon atoms diffuse through the interstitial spaces between the iron atoms in the steel’s crystal lattice.

- Vacancy diffusion:In this mechanism, carbon atoms diffuse by jumping into vacant lattice sites in the steel’s crystal lattice.

- Dislocation diffusion:In this mechanism, carbon atoms diffuse along dislocations, which are line defects in the steel’s crystal lattice.

Effects of Carbon Diffusion on Steel Properties

Carbon diffusion has a significant impact on the mechanical properties of steel. The amount of carbon in steel determines its hardness, strength, and toughness. Steel with a higher carbon content is harder and stronger, but less ductile than steel with a lower carbon content.Carbon

diffusion also affects the microstructure of steel. Steel with a higher carbon content has a finer grain structure than steel with a lower carbon content. This finer grain structure makes the steel stronger and more resistant to wear.Carbon diffusion is used to enhance the properties of steel in a variety of ways.

For example, steel can be carburized to increase its hardness and strength. Carburizing is a process in which steel is heated in the presence of a carbon-rich atmosphere, which causes carbon to diffuse into the steel.

Applications of Carbon Diffusion in Steel Processing

Carbon diffusion plays a vital role in steel heat treatment processes. Heat treatment is a process in which steel is heated and cooled in a controlled manner to change its properties. Carbon diffusion occurs during heat treatment, and it is responsible for the changes in the steel’s microstructure and properties.Carbon

diffusion is also used to create different grades of steel. Different grades of steel have different carbon contents, and this difference in carbon content affects the steel’s properties. For example, low-carbon steel is used for making sheet metal and wire, while high-carbon steel is used for making tools and machinery.Carbon

diffusion is also used in a variety of industrial applications. For example, carbon diffusion is used to create carbon-coated steel, which is used in a variety of applications, including automotive parts and medical devices.

Case Studies and Real-World Examples: Carbon Is Allowed To Diffuse Through A Steel

There are many case studies and real-world examples of carbon diffusion in steel. One example is the use of carbon diffusion to create carburized steel. Carburized steel is used in a variety of applications, including gears, bearings, and cutting tools.Another

example of carbon diffusion in steel is the use of nitriding to create nitrided steel. Nitrided steel is used in a variety of applications, including firearms, cutting tools, and medical devices.Carbon diffusion is a complex process that has a significant impact on the properties of steel.

It is used in a variety of industrial applications to create steel with the desired properties.

FAQ Resource

What is carbon diffusion?

Carbon diffusion is the movement of carbon atoms through the interstitial spaces in a steel lattice.

How does carbon diffusion affect the properties of steel?

Carbon diffusion can significantly alter the mechanical properties, microstructure, and overall quality of steel.

What are some applications of carbon diffusion in steel processing?

Carbon diffusion is used in various steel processing applications, including heat treatment, carburizing, and decarburizing.