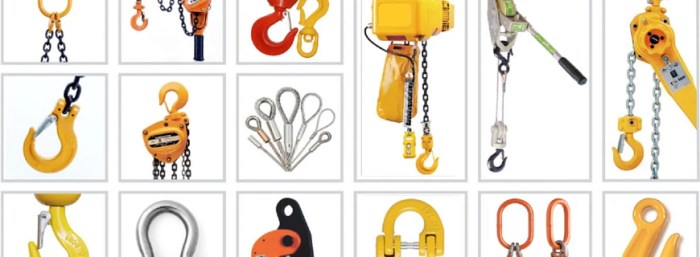

All rigging equipment must be inspected to ensure the safety of personnel and the integrity of the equipment. This article provides a comprehensive overview of the inspection process, including frequency, procedures, documentation, training, maintenance, repair, and regulatory compliance.

Regular inspections are essential for identifying potential hazards, preventing accidents, and ensuring that rigging equipment meets safety standards. By following the guidelines Artikeld in this article, organizations can effectively manage their rigging equipment and minimize the risks associated with its use.

Inspection Frequency

Rigging equipment should be inspected regularly to ensure its safety and functionality. The recommended inspection frequency depends on several factors, including the type of equipment, its usage, and the environment in which it is used. The following table provides general guidelines for inspection intervals:

| Type of Rigging Equipment | Inspection Interval |

|---|---|

| Wire rope slings | Monthly or before each use |

| Chain slings | Monthly or before each use |

| Web slings | Quarterly or before each use |

| Hoists and cranes | Annually or as per manufacturer’s recommendations |

| Lifting hooks | Quarterly or before each use |

| Shackles | Quarterly or before each use |

Inspection Procedures, All rigging equipment must be inspected

Rigging equipment inspections should be conducted by qualified personnel following established procedures. The following steps provide a general overview of the inspection process:

- Visual Inspection:Examine the equipment for any visible damage, such as cracks, dents, corrosion, or wear.

- Load Testing:Test the equipment under a load that is at least equal to its rated capacity. Observe the equipment for any signs of deformation or failure.

- Functional Tests:Test the equipment’s functionality, such as its ability to lift and lower loads smoothly and securely.

- Documentation:Record the results of the inspection and any defects found on an inspection report.

Popular Questions: All Rigging Equipment Must Be Inspected

How often should rigging equipment be inspected?

The frequency of inspections varies depending on the type of equipment and its usage. Refer to the table in the article for specific intervals.

What are the key steps involved in inspecting rigging equipment?

Visual checks, load testing, and functional tests are essential steps in the inspection process. A detailed checklist is provided in the article.

Why is documentation important for rigging equipment inspections?

Documentation provides a record of inspections, identifies any defects, and ensures accountability. A sample inspection report template is included in the article.